Quick Details

Application: Widely

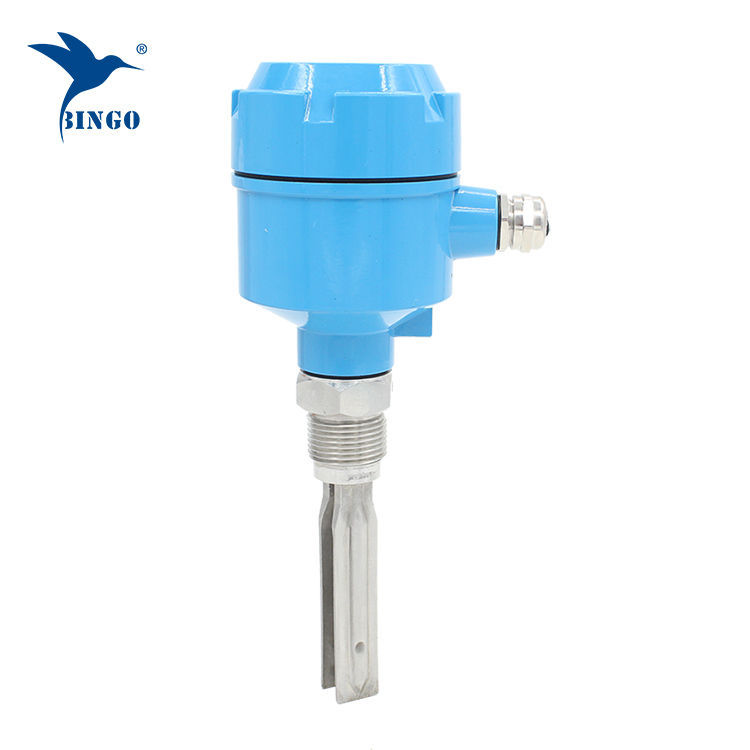

Material: Stainless Steel

Power supply: DC24V or AC220V 50/60Hz

Properties

For cement, metallurgy , coal , feed, grain, steel, power plants , sewage treatment, food and beverage, pharmaceutical and other lines Industry, especially in the conductive material , material properties ( state , humidity , dielectric constant , density, etc. ) often change , safety requirements

Higher operating conditions can be well used , can be used for good mobility solid materials , liquid level monitoring of the material in the cement silo , powder

Dusty warehouse, ash silo , tank , tanks, fermentation tanks , etc. level monitoring has been widely used. This product reliability, maintenance-free, spirit

High sensitivity , easy to put into operation without the need for calibration .

Works

It is a new level switch . It is the use of a tuning fork vibration theory designed and manufactured .

It is in the tuning fork level switch sensor bar base, driven by a tuning fork piezoelectric wafer sticks, and a piezoelectric wafer acceptance by another vibration signals , the vibration signal to be recycled , and the sensor bar to resonate . When the material in contact with the sensor bar , the vibration signal becomes smaller until it stops resonance, the control circuit will output electrical contact signal . Rod sensitivity due to induction from the front to the rear turn weakened the natural principle , so when material inside the tank around with buckets stacked up , touching sensor bar stand < back > or when nesting , will not generate an error signal .

Simply put, the piezoelectric crystal tuning fork excitation produces mechanical vibrations which has a certain frequency and amplitude . When the tuning fork is liquid or solid immersion , the tuning fork vibration frequency and amplitude will change. This frequency change detected by the electronic circuit and outputting a switch .

Scope and characteristics

It is a new level switch . Suitable for almost all liquid media , but also suitable for measuring free-flowing medium-density solid powder or granules. As the tuning fork level switch basically no moving parts , mechanical wear comparison , it is therefore no maintenance and adjustment, easy to use.

In addition, the level switch to new technologies and the use of foreign imported chips, has a long life , stable performance, safe and reliable , and adaptable ( different electrical parameters measured medium density shall not affect the measurement ) , without adjustment ( regardless what the media do not require on-site measurement calibration ) and freedom from maintenance , which is widely used in metallurgy , building materials , chemical industry, light industry, food and other industries in the level of process control .

Benefits

Versatility : can be applied to various conductive and non-conductive media measurement , such as liquid , viscous , granules, powders

Fly ash : can be anti-adhesion : the use of patented anti-adhesion circuit can eliminate the adhesion of the material generated false signals .

Detachable probe : no cables between the controller and the probe connected to the controller can be removed at any time replacement repair , no shadow

Rang out materials: resistant to high temperature : Suitable for -40 °C to 220 °C working environment.

Output Type : A DPDT relay output , while a status light to display the output state , and 0 to 30 seconds delay function.